Want to see Liondell’s process from start to finish in a real-time case study? At Liondell we don’t just design for success- we supervise the production of injection moulded parts from start to finish.

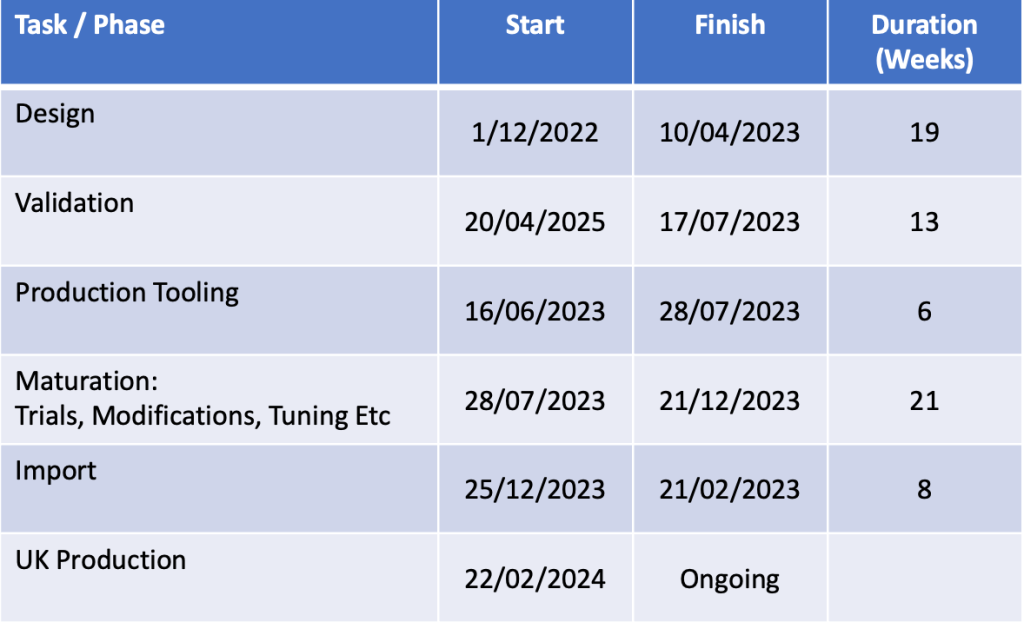

This is a project our team completed over a year ago, that began in November 2022 and finalised in February of 2024.

Read below to see what we do and how we worked with our valued client to create excellent results.

Index

- Scope

- Design

- Design for Manufacture

- Fill and Flow Analysis

- 3D Modelling and Data Control

- 2D Drawings

- Validation Phase (Rapid Prototyping)

- GA Review

- Process Development

- Tool Trials

- Dimensional Reporting

- Client Fit & Function Tests

- Virtual Toolchecking

- Supporting the Moulder

- Project Timeline

- Conclusion

Scope

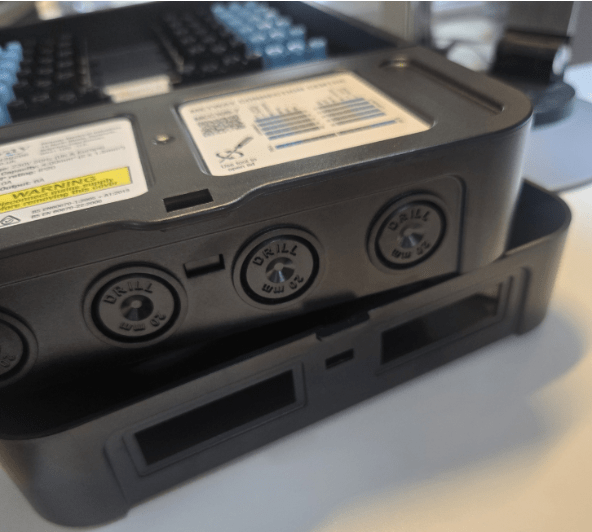

In this case, the client had existing parts which had been in production for over 10 years. The product needed to be refreshed cosmetically, and weight reduction was required to bring unit costs down.

Additional versions of the control module were required for variations in connection type and a half size MCC5 unit to be developed alongside.

During the design phase we liaised extensively with the client- who had his own chair and coffee mug in our office for a couple of months– and the PCB designer to make sure that all the parts were satisfactory.

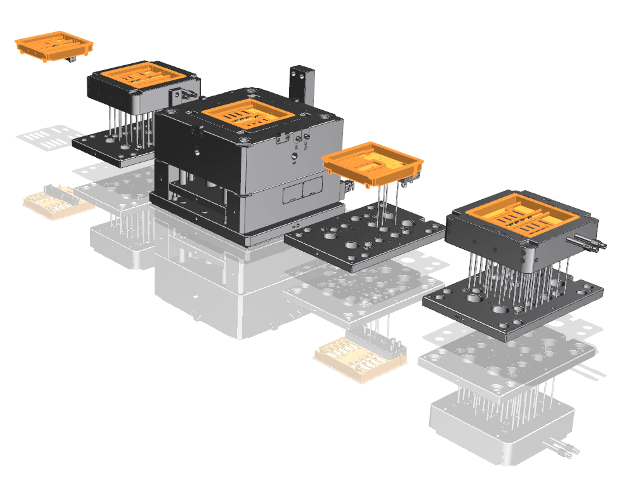

To meet the clients tooling budget, Liondell quoted based on multiple changeover inserted tooling.

In all 27 parts were made from 11 mould tools.

Design of Product

We noticed that the competitor’s product and the client’s existing unit were both utilitarian looking. Not a lot of styling had been applied, and they both relied on ribbing for strength.

When our product was designed, we improved the styling while always having ‘Design for Manufacture’ in mind at the forefront of the process.

Our decades of experience in the plastics industry, not just in consumer goods but also in Automotive, Aerospace and Packaging industries, allowed us to refer back to previous lessons learned and borrow ideas from projects we had previously completed.

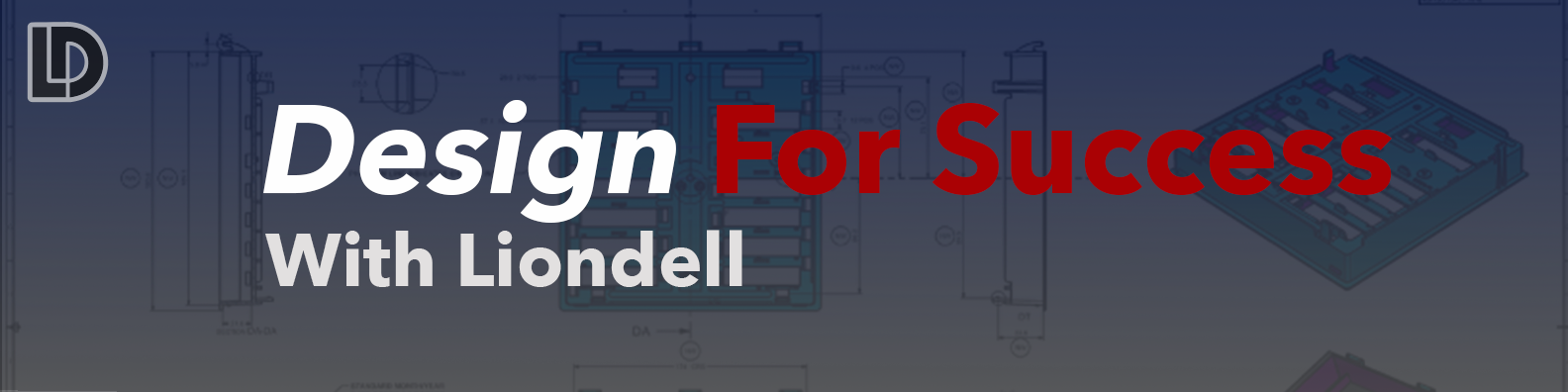

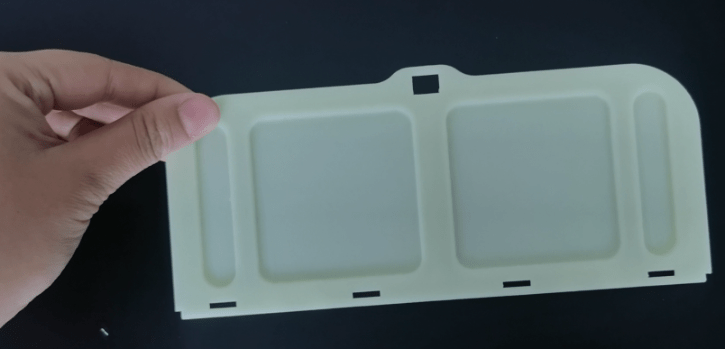

In this case, an Automotive project came to mind where ribbing was avoided, to be replaced by a ‘constant wall’ thickness, castellated design.

This design is attractive while simultaneously eliminating sink marks that are the hallmark off ribbing plastic parts.

The castellated sections act like ribs as the sectional modulus is increased.

During this phase we also conducted Flow Analysis to check that the process would be able to fill the cavity without creating distortion, weld lines or excessive pressures.

See below screen shot of the constant wall design:

Design for Manufacture

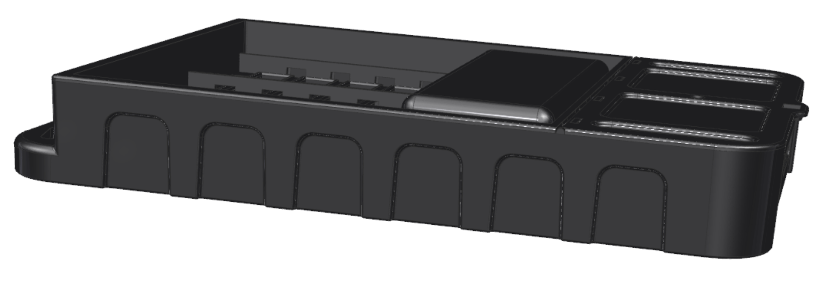

Fill and Flow Analysis

During the design process we checked that the parts design was feasible to manufacture, from a moulding perspective as well as a tooling perspective.

See below screen shot of a flow simulation (MFA) that was run on the largest component. (Rear Case)

The X shaped section was specifically designed into the Rear Case to promote flow into the corners of the part. This has the effect of balancing fill and reducing in-build stresses into the part that can cause distortion.

3D Modelling and Data Control

During the design process we made several revision changes. It is of paramount importance that these are tracked and logged properly on our system.

Meticulous records are held on our bespoke CRM database which correspond to files held in our SharePoint folders.

2D drawings

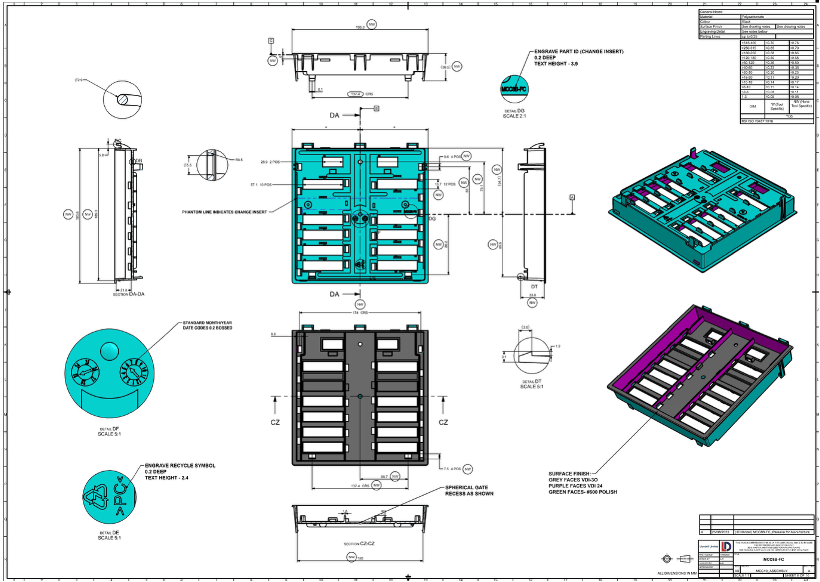

From our 3D models, 2D drawings were generated to provide a basis for dimension reporting at approval stages.

During the DFM and Tool design processes, Liondell considered the requirements for multiple insert changeovers within the tooling to accommodate various versions. The moulding Company would have to perform this process multiple times during the life of the tooling, so it was important to simplify the design as much as possible.

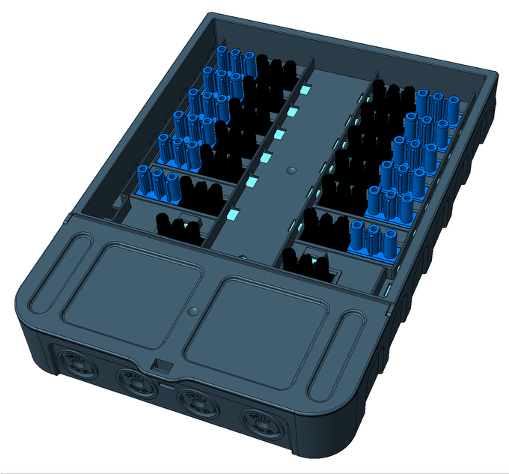

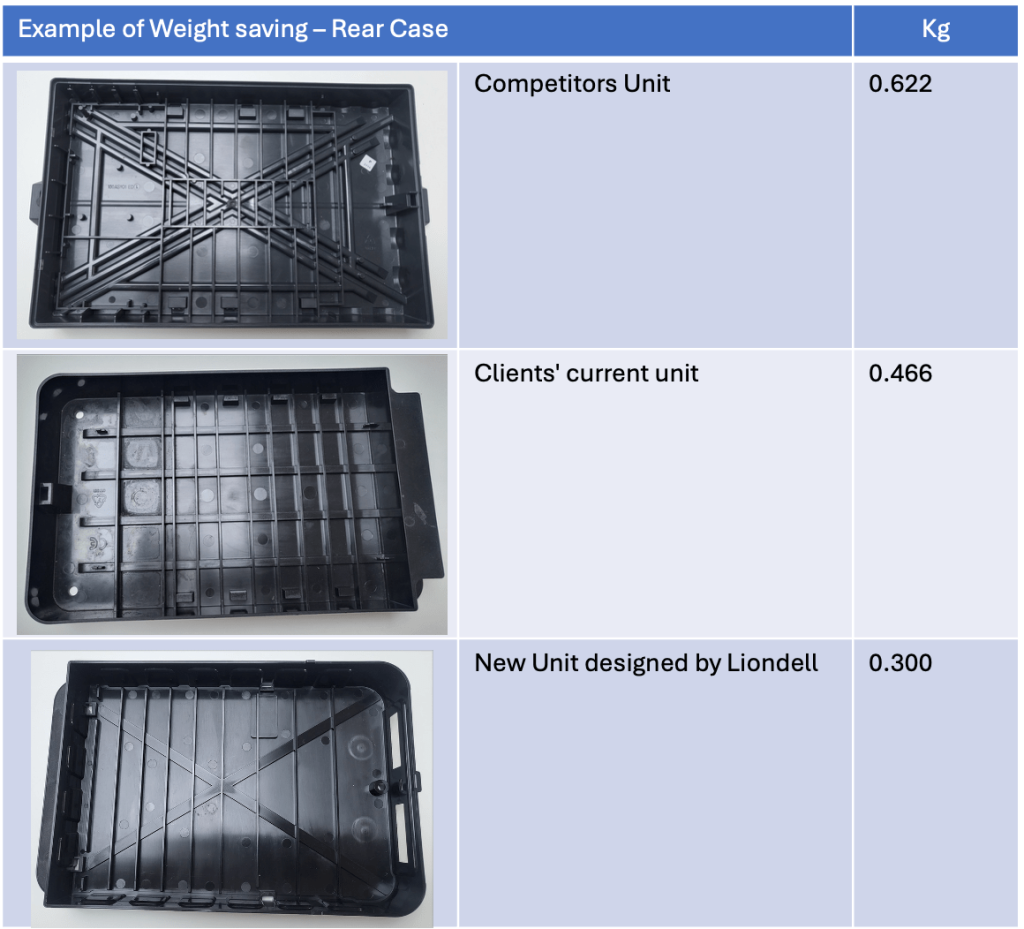

When were happy with the basic fill of the part, we could progress to add the finer details. As one of the main drivers for re-design was weight savings, we achieved significant reductions as shown below:

The weight savings on a single component are 55%

Over a single year’s production of 100,000 units this would equate to 16.6 Tonnes of material with a value of approx. £83,000 (FRPC @£5,000/tonne)

Validation Phase (Rapid Prototypes)

Once the design phase was complete, we supplied a considerable quantity of functional prototype units for the client to test and use for fit and function.

All the ancillary plastic parts could be assembled along with PCBs for both MCC10 and MCC5 products.

The parts shown below are MJF (Multi Jet Fusion) 3D prints which were printed and delivered in a 2-week period. This material is a Nylon which was chosen due to the numerous working clips that need to function on assembly. SLA 3D prints are not suitable for this.

Validation Phase (Adjustments)

Although the existing unit worked well, there were several improvements to be made to enhance the user’s experience.

One of the features was to incorporate a hinged terminal cover. Whilst the old unit had a loose cover that could get misplaced, the new hinged design would stay attached and had improved tamper proof features.

The design was time consuming and did change during development after review of 3D printed samples.

An example of the original hinged design (Early SLA 3D Print) below left, and an example of the developed design subsequently used in production, right.

- Alternative Power connections were incorporated for MCC10 & MCC5 versions.

- Originally a single power option, the client wanted to add ‘panel mount’ type connectors. The design was changed to accommodate this.

Other changes incorporated after the initial design brief:

- Additional Version with protection cover for Bluetooth module added

- An LED power indicator was added

GA Review

The GA review incorporates our own checklists to ensure that certain features are not overlooked.

The review is generated by Liondell and followed by our toolmaking partners who update their tooling GA’s accordingly until we and the client approve for start of manufacture.

Every week, photo progress and Gannt chart timing plans are submitted through to the tool trial date (T1).

Process Development

Tool Trials

Our own independent quality manager is based nearby to our toolmaking partners. Their role is to liaise with the toolmaker from the very start until tooling is approved to ship.

One of the key tasks is to attend the tooling trials which follow immediately after tool manufacture completion.

Usually, these trials take a whole day and there could be several going on simultaneously. Our manager must be able to coordinate this and take notes, photos and videos to compile a detailed trial report at the end of the day.

These reports are with us in the UK sometimes only hours after the trials have taken place.

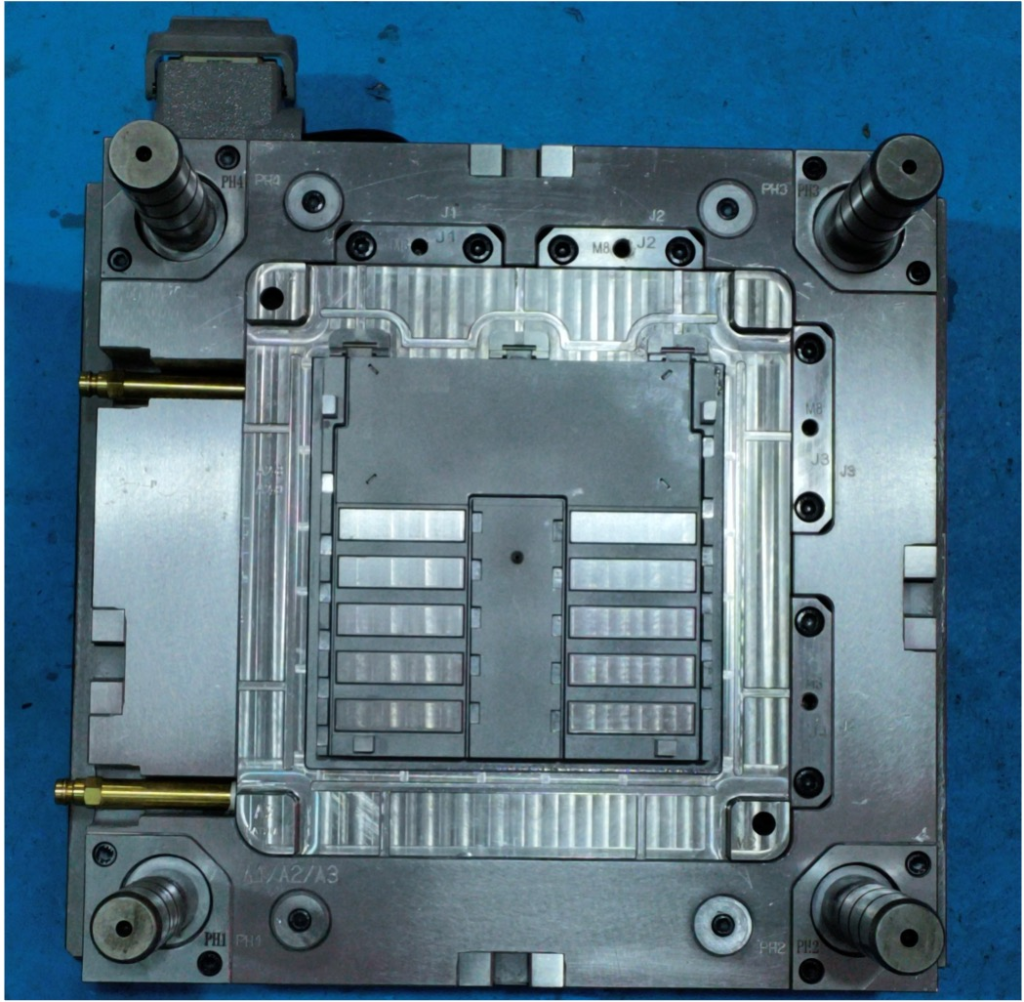

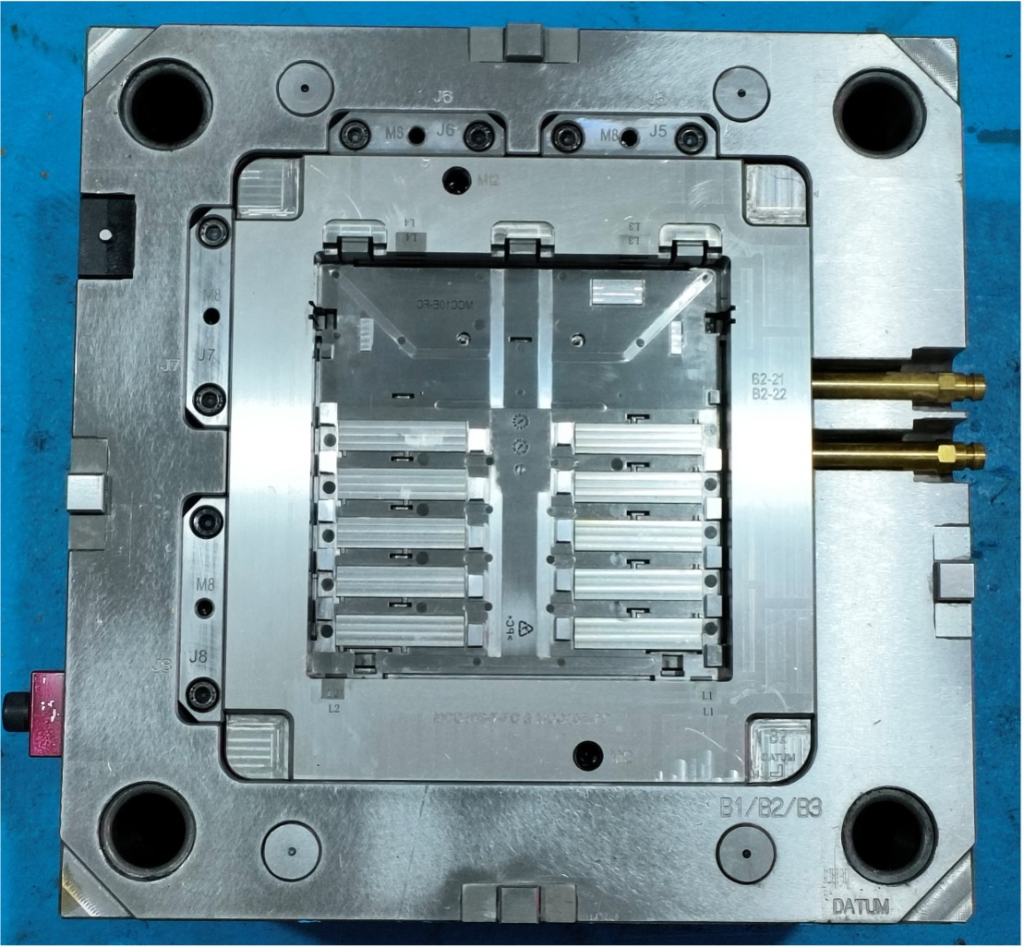

See below example – T1 Front Cover Tool

Dimensional Reporting

After each trial stage, samples are submitted to the quality department for dimensional checking.

This will repeat 2 times, when T3 parts are usually approved by the client and tools given the green light to ship or Air freight to UK.

Client Fit & Function Tests

The client was supplied with several samples from each trial for fit and function testing for both MCC10 & MCC5 Units

- PCB into Rear Case

- Front Covers assembled to Rear Case

- Hinged Lid to various Front Covers

- Side Latch Plugs to PCB & various Front Covers

- Electrical connections

Virtual Tool Checking

Prior to the tools leaving the factory, our quality manager will be present to run through our VTC (Virtual Tool Check) document, which outlines the checks to be carried out and recorded in very fine detail with the aid of videos and high-resolution photographs.

Supporting the Moulder

Prior to tooling delivery, Liondell generated change-over instruction documents for the moulding company to use.

See Image below:

Project Timeline

Conclusion

We hope you enjoyed our thorough run-down of this previous project, and learnt more about how we apply our expertise to every stage of the design and production process.

Contact us for enquiries and further information, and get your free quote today.

Visit our Linkedin to connect with the team and keep up to date with us live.