When it comes to plastic product design, you need a team with extensive industry experience and a proven track record of delivering high-quality solutions. That’s where Liondell comes in.

At Liondell, we bring together many years of experience in toolmaking, moulding, and product development to help our clients design and develop plastic parts and assemblies. We have worked in various industries, including Automotive, Aerospace, Medical applications, personal care, adhesives and sealants, packaging, and building products, to name a few.

Our emphasis is always on designing parts that meet our clients’ specific design brief for fit, function, and aesthetics. We take a collaborative approach to our work, working closely with our clients to understand their needs and ensure that our designs align with their vision.

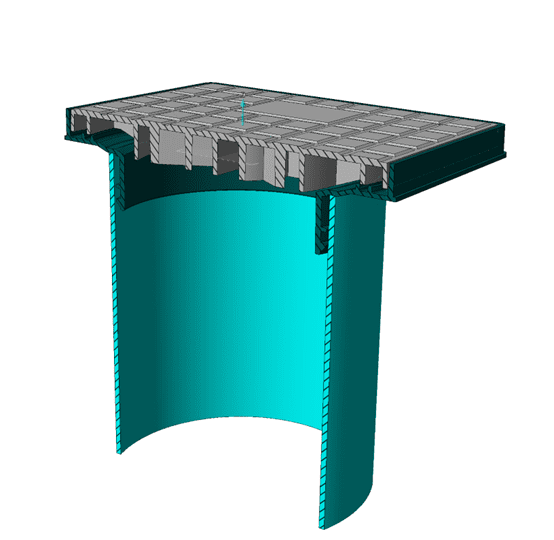

One of the key strengths of Liondell is our knowledge of plastic and rubber moulding processes. We design parts that are feasible for manufacturing right from the start, which helps us to save our clients time and money. Using the latest software tools, we can quickly and efficiently design any type of plastic part and run flow analysis to optimize feed positions and predict potential defects that can be designed out at the initial stages.

We have extensive experience working with a broad range of plastic resin types and grades. If we require specialist input, then we would involve material suppliers at an early stage to get independent input regarding material selection. Our design for manufacture (DFM) process is incorporated into our design process, so when the client signs off on the design, we are ready to go to tooling immediately.

At Liondell, we are committed to staying up-to-date with the latest industry trends and using the latest technology to deliver the best possible results for our clients. We use the latest VISI Cad/Flow and Siemens NX software to ensure that our designs are of the highest quality and are manufacturable.

When you choose Liondell for your plastic product design needs, you can be confident that you are working with a team of experts who will deliver the results you need, on time and on budget. For more information on our product design services, call us on +44 (0)2392 429 424 or email us directly.