Trial Runs

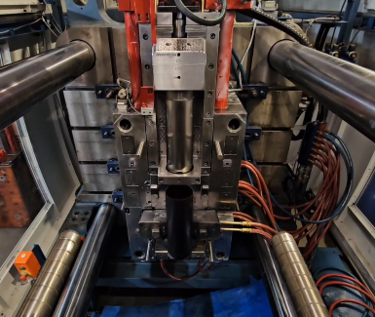

Liondell’s tool trial runs provide the essential step between initial mould samples and full-scale production.

By running controlled, low-volume trials, we verify that your tooling performs as intended, assess part quality and identify refinements before committing to full manufacturing. This early validation reduces risk, improves reliability and ensures your project enters production with confidence.

With over 50 years of combined experience, Liondell delivers precision-led trial runs that support SMEs through to major manufacturers. Our UK-based engineering team works with trusted global partners, giving clients flexible trial options and dependable risk reduction before large-scale investment. Tool trial runs at Liondell are conducted under production-like conditions, using the same materials, settings and processes as full-scale manufacture. This allows us to:

- Validate tooling for durability and repeatability

- Identify performance or design concerns early

- Produce reliable data for QA and regulatory approvals

- Supply test parts for assembly checks or market trials

The following will be ensured:

Tool Validation

Confirming that moulds meet design intent and production standards.

Low-Volume Trial Moulding

Limited part runs to replicate production conditions.

QA Testing

Checking dimensions, tolerances and material performance.

Design Refinement

Identifying and correcting issues before scaling up.

Smooth Scale-Up

Ensuring seamless transition into full production tooling.

We support industries including automotive, medical, consumer goods, electronics, industrial and packaging. By validating your tooling under real-world conditions, Liondell helps you prevent costly errors, refine performance and move toward production with certainty.

How to get started

Next steps

1

Contact

us

Call or send us an email with your project requirements.

2

We Respond

We will acknowledge your inquiry and aim to respond within 24 hours

3

Project Launch

Our goal is to make our clients happy with the whole process and the results within the agreed timeline.

It starts with a 5-minute introduction call