High-performance production tooling engineered for durability, precision, and long-term manufacturing efficiency.

Liondell delivers production tooling that manufacturers trust for consistent, high-volume output. We provide:

- Production tooling engineered for longevity

- Precision toolmaking and validation

- UK and overseas manufacturing options

- Full logistics and maintenance support

- Consistent, repeatable performance at scale

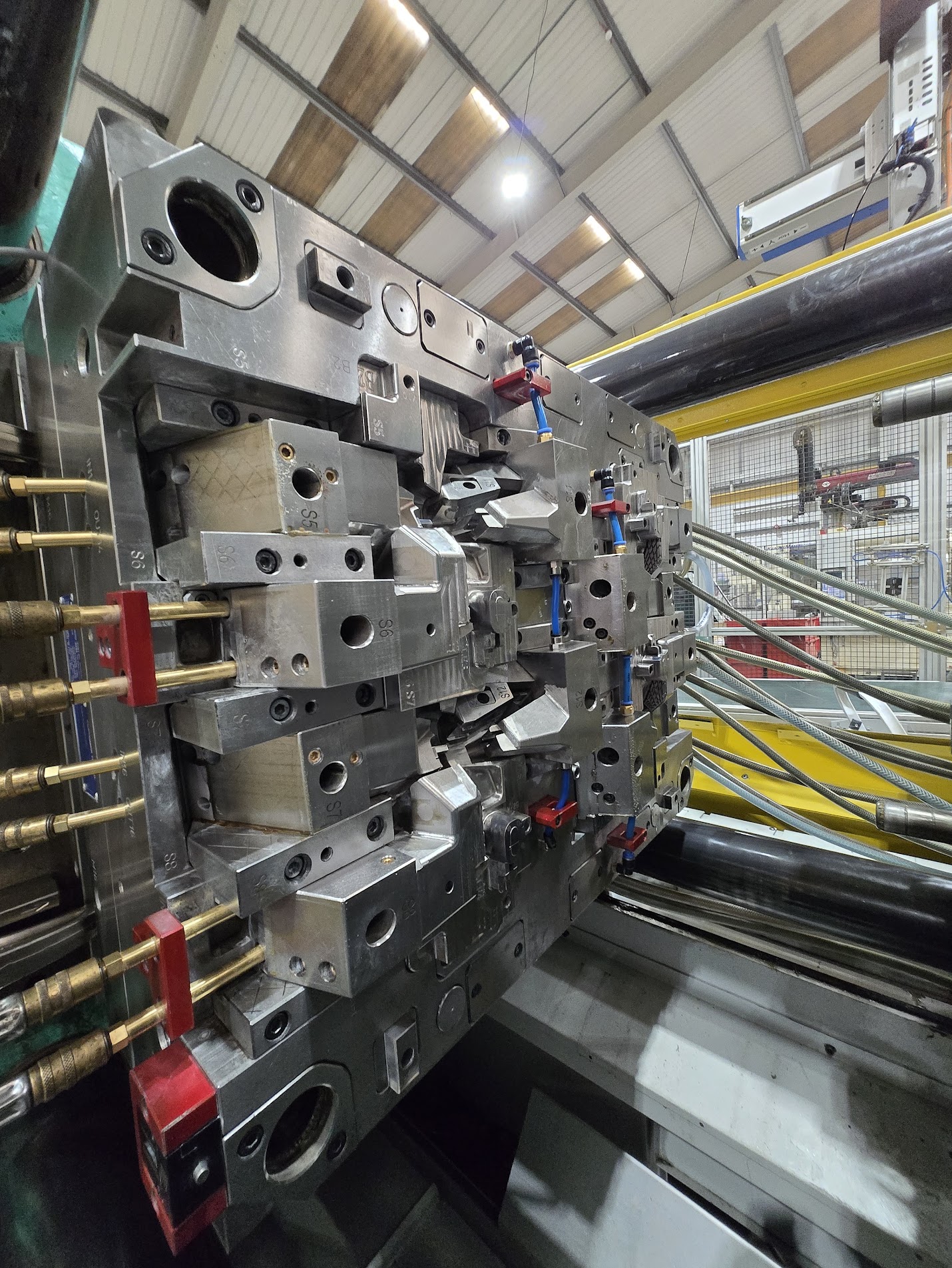

Every mould is engineered to withstand demanding production cycles, maintain dimensional accuracy and operate with maximum efficiency. Our UK-based engineering team oversees each project from concept through to final tool validation, supported by trusted international tooling partners who offer flexible options in cost, capability and lead time.

By combining precision-led design with decades of hands-on toolmaking experience, we ensure each tool is built for long-term durability and low maintenance requirements. From the first CAD model to the final trial, every detail is considered, tested and refined so the tool performs seamlessly in real-world production.

End-To-End Tooling

Our solutions are built on precision engineering and proven manufacturing control. They include:

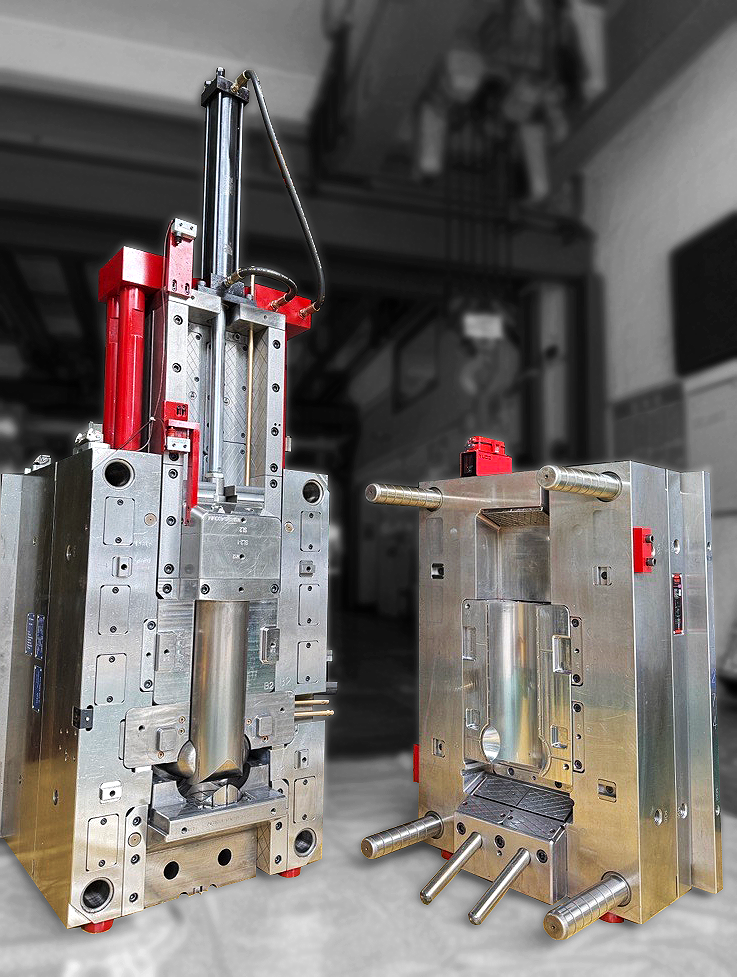

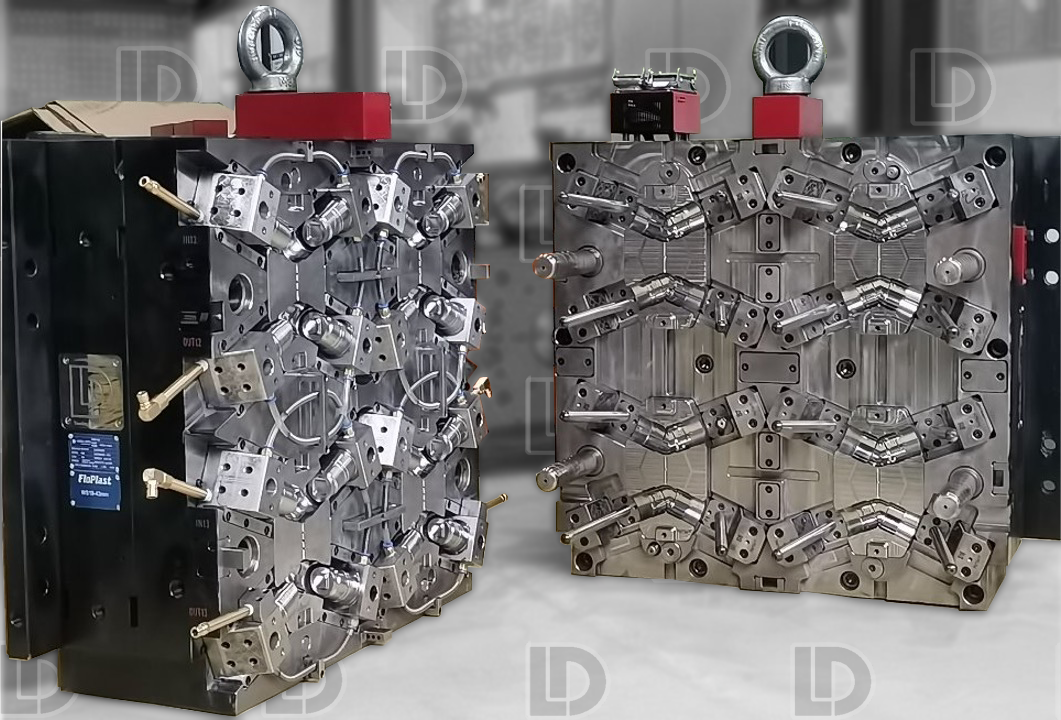

Our full-scale production moulds are designed for high-volume output and long-term performance. Built from quality steels and engineered for repeatability, each tool is manufactured to withstand thousands—or even millions—of cycles without compromising part quality. We consider geometry, material flow, cooling efficiency and processing constraints from the outset to create reliable, stable moulds that deliver consistent results in demanding production environments.

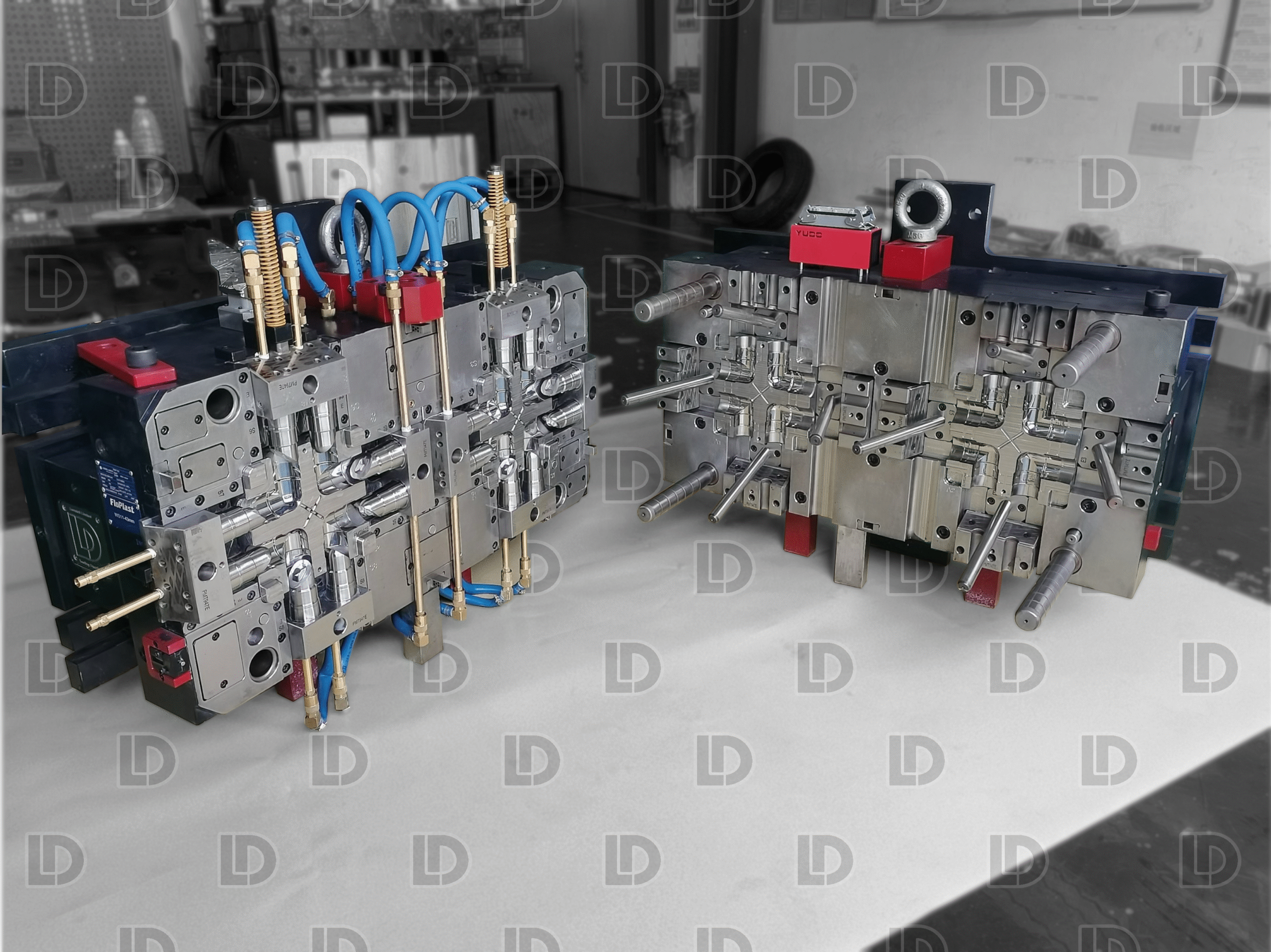

Liondell’s precision toolmaking ensures the accuracy needed for modern injection moulding. Every cavity, core and moving element is cut, fitted and checked to meet strict tolerances. Using advanced machining processes and industry-proven toolmaking standards, we achieve dimensional stability, optimised cooling layouts and clean, reliable action patterns. The result is tooling that not only produces high-quality parts but also reduces cycle times and supports efficient long-term production.

We offer both UK-based toolmaking and trusted overseas manufacturing options, giving clients flexibility in budget, timelines and specification. Overseas tooling can offer substantial cost advantages, while UK tooling provides rapid communication and shorter lead times. All partners are fully vetted, audited and aligned with our engineering expectations. Regardless of production location, every tool is overseen and approved by our UK team, ensuring you receive consistent quality and dependable performance across all volumes.

Every tool undergoes a rigorous validation process before handover. Tool trials are performed under production-like conditions to verify part quality, cycle repeatability and mechanical reliability. This includes dimensional checks, mould flow evaluation, material performance assessment and optimisation where required. Only when the tool meets the agreed criteria do we approve it for shipment or production. Our aim is to eliminate startup issues and ensure the tooling performs exactly as expected from day one.

Shipping production tooling requires specialist knowledge, and Liondell supports clients throughout the logistics process. With experience coordinating thousands of tools worldwide, we advise on the best transportation method—road, sea, air or rail—depending on budget and urgency. We also manage packaging specifications, export documentation and risk assessments. Cargo insurance is available to protect against unlikely transit damage, giving clients confidence and security throughout the journey. Whether the tooling is delivered locally or internationally, our processes ensure it arrives safely and ready for production.

Production tooling requires regular maintenance to ensure it performs reliably throughout its lifecycle. Liondell provides full guidance on upkeep and offers additional support where needed. Our UK toolmaking partners can assist with preventive maintenance, refurbishment, repairs or modifications. If future design changes are required, our engineering team can review, adapt and revalidate the tool. Aftersales is a core part of our service—we remain available long after delivery, ensuring your tooling continues to operate efficiently.

Durability is central to our tooling philosophy. We use high-grade steels, robust components and proven manufacturing techniques to ensure each mould can withstand demanding cycles. Cooling systems and gating layouts are engineered to maintain part consistency while minimising wear. By focusing on long-term reliability rather than short-term savings, we deliver tools that maintain accuracy, reduce downtime and extend operational life. This translates to lower maintenance costs, fewer interruptions and a significantly more efficient production process.

Cycle efficiency directly impacts output and profitability. Our tooling is designed to support fast, stable cycles by optimising cooling channels, gate design, part ejection and material flow. These engineering decisions reduce mould cooling times, minimise part defects and improve machine utilisation. Whether you're producing thousands or millions of components, tools engineered for efficient cycles increase productivity and reduce long-term manufacturing costs—delivering immediate and measurable benefits to your production line.

Tooling is a long-term investment, and Liondell provides support throughout its operational life. From routine maintenance recommendations to troubleshooting unexpected production issues, we help ensure your moulds stay reliable and efficient. Our team can also assist with tool optimisation, steel replacements, component upgrades or full refurbishments as needed. This ongoing involvement allows clients to run stable production with minimal downtime, extending the lifespan and return on investment of every mould.

How to get started

Next steps

1

Contact

us

Call or send us an email with your project requirements.

2

We Respond

We will acknowledge your inquiry and aim to respond within 24 hours

3

Project Launch

Our goal is to make our clients happy with the whole process and the results within the agreed timeline.

It starts with a 5-minute introduction call