Liondell’s Design for Manufacture (DFM) services help businesses refine plastic component designs so they can be produced efficiently, reliably and without unnecessary cost. By addressing manufacturability early, we reduce risk, avoid redesigns and ensure every part is optimised before tooling begins. The result is smarter design that leads to smoother, more predictable production.

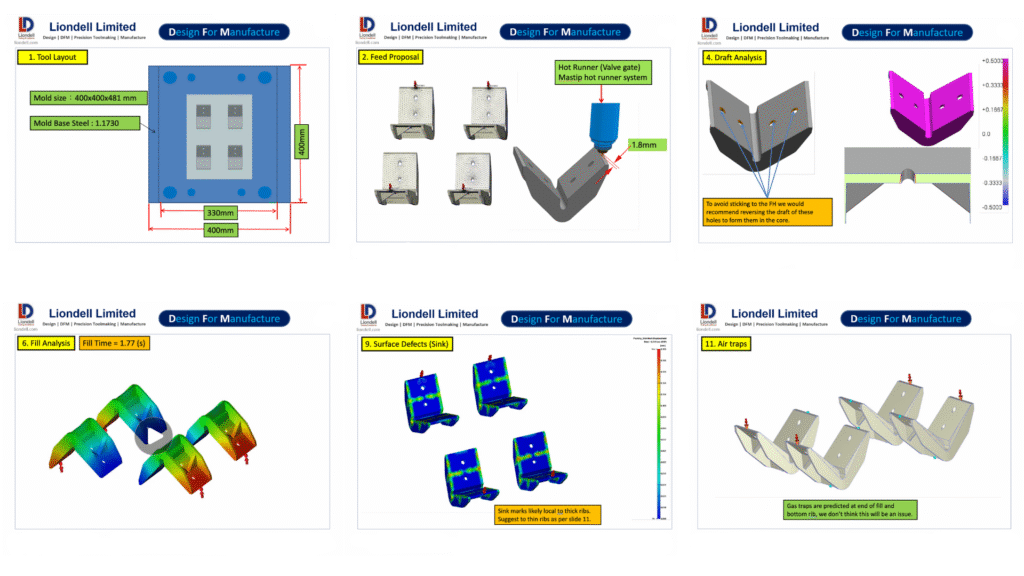

Our Design for Manufacture process combines detailed CAD analysis, practical engineering insight and decades of tooling experience. We offer a focused set of services to strengthen your design from the outset:

- Design Reviews

- CAD Analysis

- Mould Flow Simulation

- Cost Optimisation

- Tooling Recommendations

These evaluation steps uncover issues such as weak points, undercuts, wall-thickness concerns and potential defect areas. Mould flow simulation predicts how material fills the tool, helping prevent warping, voids and sink marks. Every recommendation is rooted in real production requirements and delivered by a UK-based, family-run engineering team with over 50 years of combined experience.

Our structured workflow keeps your project moving efficiently and ensures every stage is clear and controlled:

Initial Review

Understanding your design goals and current CAD models.

Analysis & Simulation

Using CAD checks and mould flow to predict performance.

Refinement & Recommendations

Improving manufacturability, tooling and cost.

Prototype (Optional)

Early testing before full-scale tooling.

Design Approval

A production-ready design validated for manufacture.

We support sectors including automotive, medical, industrial, consumer goods, electronics and packaging. With Liondell, your design becomes practical, efficient and ready for tooling—giving you confidence before production begins.

How to get started

Next steps

1

Contact

us

Call or send us an email with your project requirements.

2

We Respond

We will acknowledge your inquiry and aim to respond within 24 hours

3

Project Launch

Our goal is to make our clients happy with the whole process and the results within the agreed timeline.

It starts with a 5-minute introduction call