At Liondell, we are committed to staying up to date with the latest trends in the injection moulding and plastics industry. We use the latest technology to deliver the best results for our clients. Moldex 3D, VISI CAD/Flow and Siemens NX are all tools in our arsenal to ensure that our designs are of the highest quality and are manufacturable.

We’ll take you through the programs we use and how we use them to deliver excellent results for your plastic injection moulding projects.

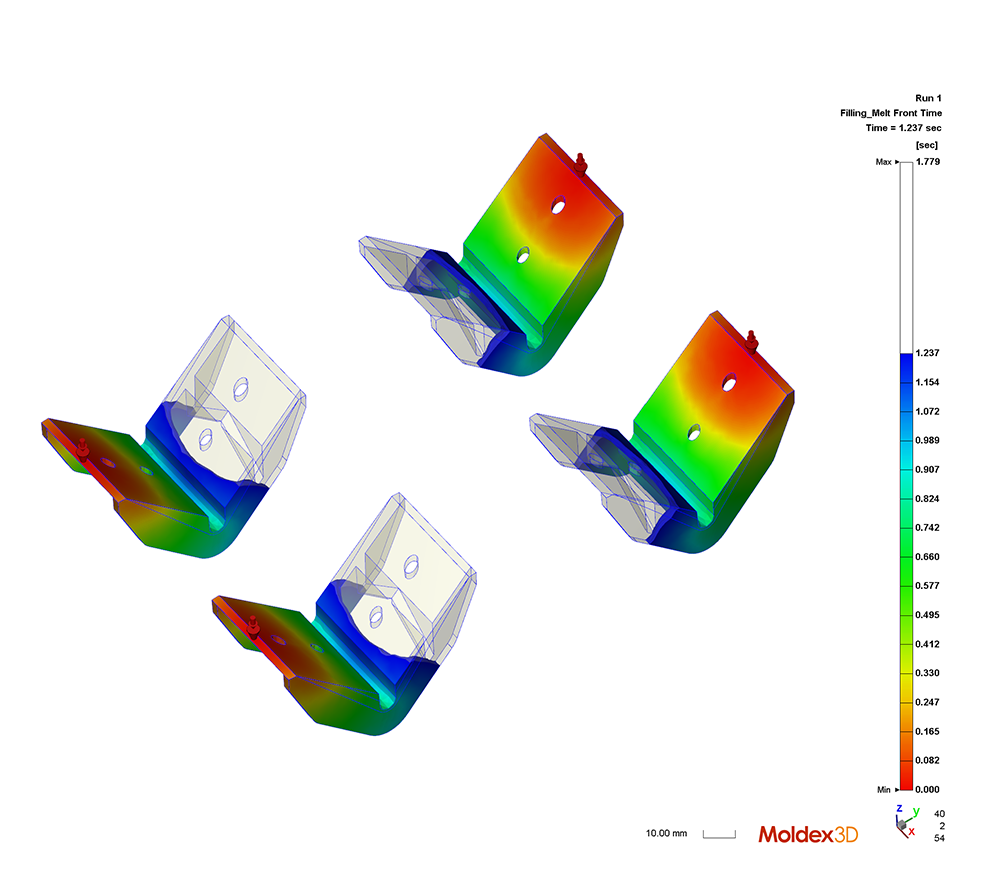

Moldex3D

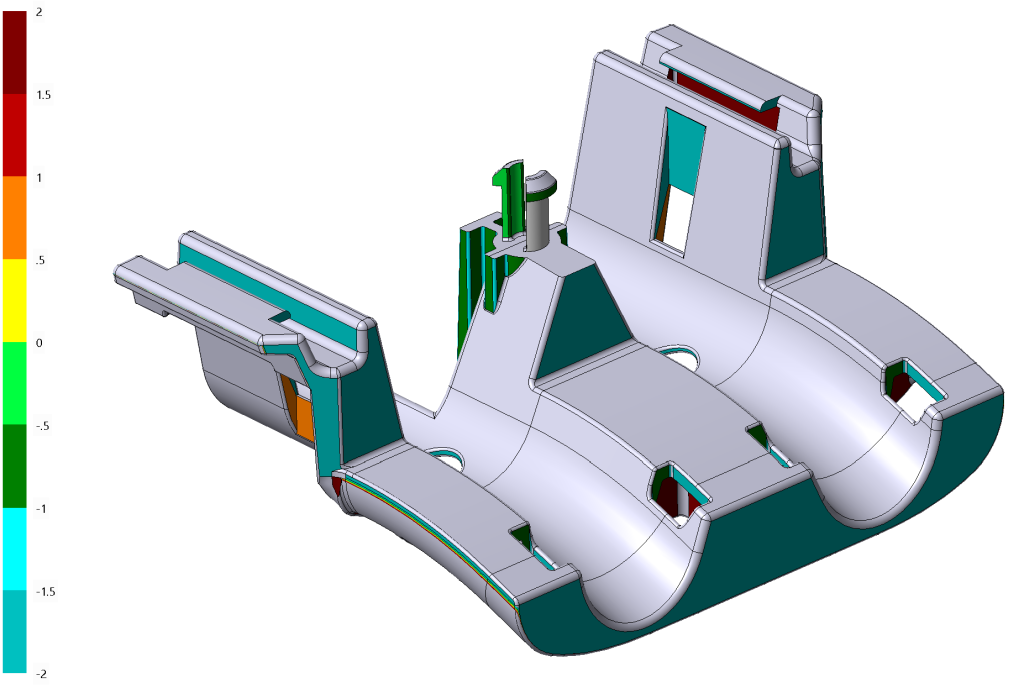

Moldex3D is advanced simulation software for plastic injection moulding. It helps our engineers analyse, optimise, and validate the design and manufacturing of plastic parts and moulds.

Here are some of the benefits of using Moldex3D:

- Improves Product Quality:

Detects defects like warpage, short shots, sink marks, and weld lines before production; which enables early-stage validation to avoid costly redesigns

2. Reduces Time and Cost:

Minimises trial-and-error by testing virtually prior to manufacturing of injection moulds. This significantly lowers the cost of physical prototyping.

3. Optimizes Mold Design:

Overall mold lifespan and performance is improved by fine-tuning gate location, runner balance, and cooling layout. This reduces the likelihood of production downtime caused by poor mold performance.

4. Enhances Process Control:

Predicts and controls moulding parameters for better repeatability and efficiency, providing robust data insights that help standardise production runs and simplify troubleshooting.

5. Supports Sustainable Manufacturing:

Reduces material waste and energy usage through process optimisation which enhances sustainability goals by improving resource efficiency and enabling greener manufacturing practices.

VISI Cad/Flow

VISI is a specialised CAD/CAM/CAE software suite designed for the mould industry.

What does Siemens NX do and how does it benefit our customer’s product development needs?

- Specialised Plastic Part Design

VISI is built for mould design, specifically for plastic part geometry, draft analysis and undercut detection. This ensures designs are fully optimised for injection moulding from the beginning

- Streamlined Tooling Development

Dedicated mould and electrode design modules automate core/cavity splitting, parting line creation, and component selection which results in faster, standardised tooling solutions. - Integrated Mould Flow Simulation

VISI Flow simulates material flow, weld lines, air traps, and cooling performance early in the process, helping to validate and optimise part and tool design before physical prototyping.

- Reduced Time and Cost

By combining specialised mould design tools with early simulation and automated manufacturing prep, VISI cuts down lead times, reduces costly rework, and supports quicker product delivery.

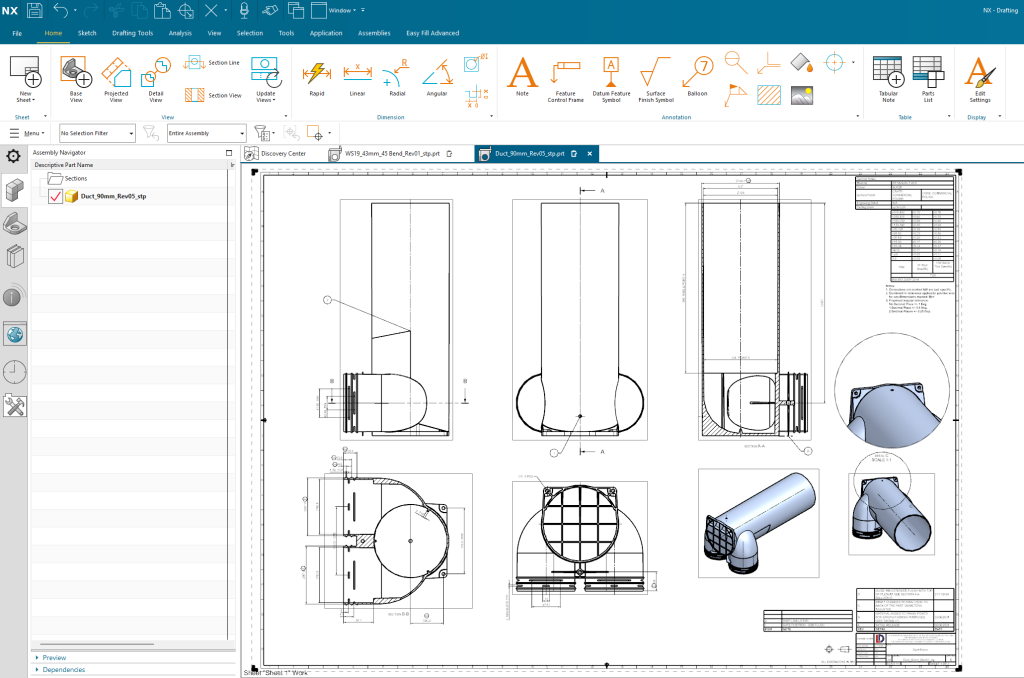

Siemens NX

Siemens NX is a high-end CAD/CAM software that we use to bring designs to life in a life-like 3D way.

What capabilities does Siemens NX offer, and how do they add value for our customers?

- High-Quality Design

Precise 3D and surface modelling ensures accurate, mould-ready parts with fewer design errors and better surface quality. - Faster Development

Integrated CAD/CAM/CAE and automation tools accelerate design and tooling, reducing time to market. - Early Simulation & Validation

Built-in mould flow analysis predicts fill, warpage, and cooling issues early—minimizing trial-and-error and physical prototyping. - Efficient Tooling

Automated creation of mould components (core/cavity, shut-offs, cooling) speeds up tooling development and supports standardization.