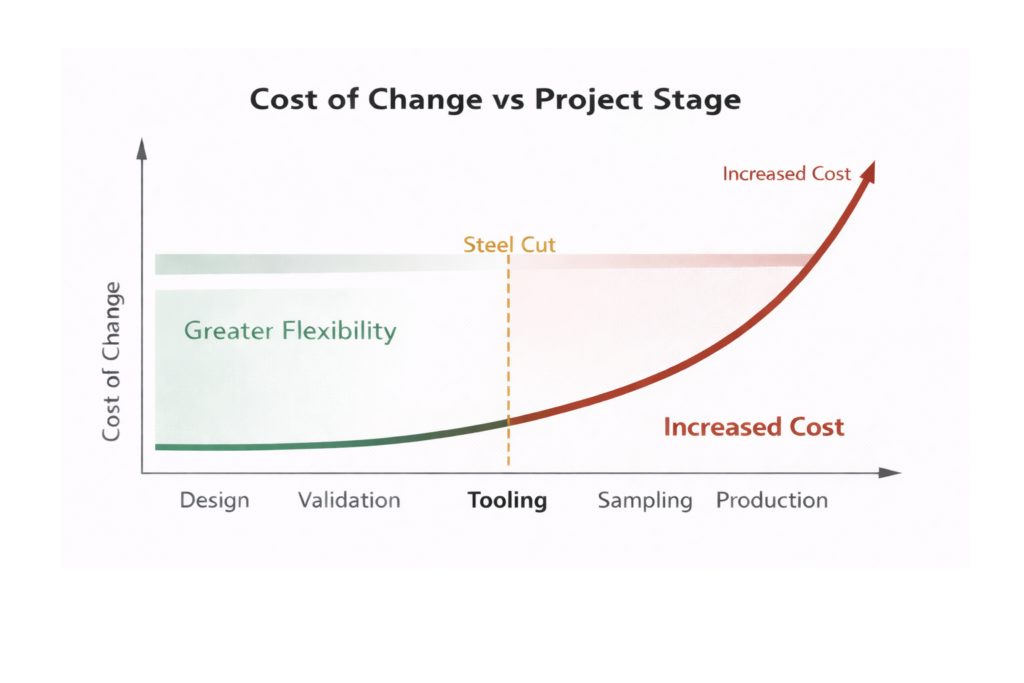

In injection mould tooling, every project has a point of no return- the moment designs become reality.

In our industry, reality means steel. But unfortunately, steel is expensive. And once it’s cut it’s difficult to make changes.

Up until that point, changes are straightforward- CAD can be adjusted and dimensions reviewed.

Ensuring that the design is correct before manufacture is where costly changes later in your injection mould tooling project can be avoided.

Why Problems Often Appear Late

When samples reveal defects it can point to issues stemming from the original design, not necessarily the moulding process.

A part may look aesthetically perfect in CAD, but the process of injection mould tooling requires a separate set of constraints:

- Will the part release cleanly from the tool?

- Are shut-off conditions robust enough to last?

- Are wall sections balanced?

- Will plastic flow well into all areas?

- Are air traps or weld lines likely?

These are not large changes to make, but left unchecked and compounded they can pose a threat to the final part.

There are many checks involved in a full DFM (Design for Manufacture) and MFA (Mould Flow Analysis) process when evaluating designs, but the above are just a few.

What Questions Should Be Answered Before Tooling?

For companies without in-house plastics expertise, the safest approach is not to rely on experience alone, but to systematically answer a small number of critical questions before committing to steel.

Out of dozens of questions that should be asked, here are just five:

1. Will the Part Release Cleanly?

Draft angles, surface textures and parting line decisions directly affect ejection.

Insufficient draft, particularly on textured surfaces, can lead to scuffing, steel drag or premature tool wear. These issues rarely appear obvious at design stage, but become immediately visible in production.

A structured draft and shut-off review removes guesswork.

2. Are Wall Sections Designed for Moulding?

Thick sections in injection moulding can create cooling imbalance, sink marks and longer cycle times.

Sudden transitions in thickness can create stress concentrations or warpage.

Balanced wall design reduces cosmetic risk and improves production efficiency. These are two factors that directly affect cost per part.

3. Has Material Flow Been Validated?

Certain risks are not visible in a static 3D model:

- Air traps

- Weld lines

- Clamp force requirements

- Fill imbalance

- Cooling performance

The above only become apparent once parts are moulded- unless they’re evaluated beforehand.

Mould flow analysis allows for accurate estimation of how the polymer will behave in the mould.

It allows fill time, flow front temperature, pressure requirements and venting considerations to be assessed before steel is cut.

Without this, projects rely on educated estimation.

4. Has the Design Been Physically Tested?

Even well-developed CAD models benefit from physical validation.

3D printed prototypes allow fit, assembly and functional testing before committing to tooling. They also provide an opportunity to optimise geometry specifically for injection mould manufacture. This is useful when designs are reverse engineered or adapted from legacy parts.

Prototyping reduces uncertainty at relatively low cost, especially compared to modifying hardened tooling.

5. Is Everyone Working from the Same Data?

One of the most common, and least discussed, causes of tooling issues is data management and control.

Out-of-date 2D drawings or 3D files can be sent to suppliers unintentionally. Email attachments and informal revision tracking create ambiguity. Once steel is machined against superseded data, rectification is rarely simple.

Clear data control, formal confirmation of tool specifications, and documented revision tracking ensure that customer requirements and tool design remain aligned.

It sounds like a lot of admin, but it protects both timeline and budget.

The Role of Structured Oversight

For companies without in-house injection mould tooling expertise, projects such as these can be daunting. And they often contain many moving parts and decisions, such as:

- Design refinement

- Tooling suppliers

- Material selection

- Mould flow analysis

- Sampling and validation

Without structured oversight, responsibilities can be unclear and assumptions can be made, making a project more complicated and potentially risky than it needs to be.

The most successful projects are when risks are identified early and accountability is made clear.

When design, tooling and supplier communication are coordinated from the outset, issues are resolved while changes are still simple.

In Conclusion

Injection mould tooling represents a significant investment. But the tool itself is rarely the real risk.

The risk lies in committing to steel before key questions have been answered.

For businesses that don’t manage injection moulding every day, having structured design evaluation, controlled data management and clear project oversight in place before tooling begins is what separates smooth launches from costly revisions.

Because once steel is cut, further changes are difficult to make.