About the Liondell family

About us

Liondell is a family-owned engineering business based on the South Coast, specialising in plastic product design, tooling and manufacturing support. With over 50 years’ combined experience, we help clients turn ideas into reliable, production-ready components and tooling.

A Family Business with a Clear Mission

At Liondell, our mission is simple: deliver precision, quality and long-term performance in every project. We approach each design and tool with the care, attention and accountability that define a family-owned business. Guided by strong values, we focus on producing solutions that not only look right but perform reliably in real-world manufacturing environments, supporting clients from concept through to production.

Expertise at Every Stage

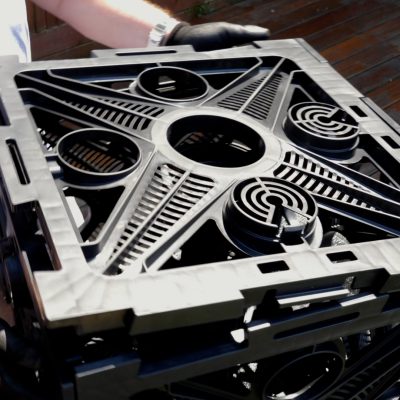

Plastic Product & Part Design

We design plastic components that balance functionality, manufacturability and visual appeal. Starting from a client brief or early sketch, we create detailed CAD models that account for material selection, wall thickness, tooling considerations and production constraints. This ensures every part is engineered to perform reliably from prototype through to full manufacture.

Re-Design of Existing Products

We support clients in improving existing plastic components by enhancing durability, correcting weaknesses and refining performance through smarter engineering. Using detailed analysis and CAD redevelopment, we optimise geometry, reduce material waste and resolve issues that may cause tooling or production challenges. The result is a more efficient, reliable and cost-effective component ready for manufacture.

In-House Concept Development

Drawing on decades of experience, we develop in-house concepts that solve common challenges in plastics manufacturing. These innovations help clients accelerate development, explore new opportunities and benchmark ideas against proven engineering principles, reducing iteration time and improving product readiness.

Integrated Design-to-Tooling

Our design work is carried out with tooling, processing and production in mind from the start. This integration eliminates unnecessary revisions and creates a seamless transition into tooling manufacture. By aligning engineering and production requirements early, we minimise delays and ensure the finished tool accurately reflects the approved design.

Turning Designs into Reliable Products

Every design undergoes refinement, testing and dimensional checks to confirm it performs as required. Our iterative process reduces risk and ensures the product is validated before tooling investment. Clients receive the confidence needed to progress, knowing the final design has been reviewed for accuracy, functionality and long-term performance.

Global Expertise in Tool Manufacture

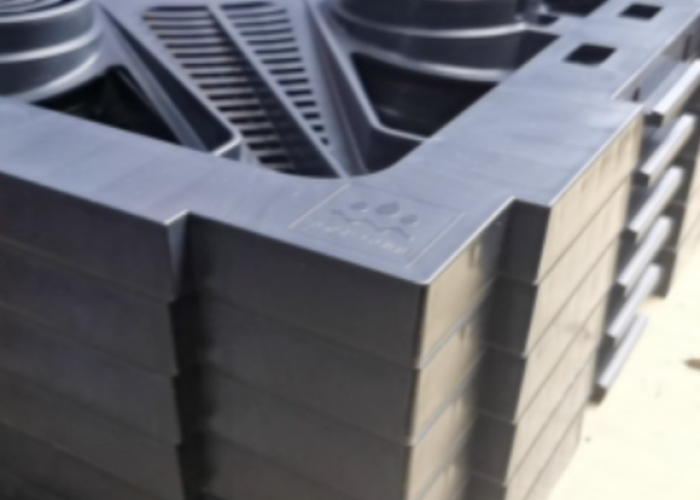

Toolmaking & Global Partners

Liondell works with vetted toolmaking partners across the UK, Europe and the Far East, ensuring high-quality tools regardless of location. Our UK team manages every project, providing consistent communication, competitive lead times, cost options and reliable tooling performance supported by global capability and long-standing manufacturing relationships.

Supporting Clients Through Production

Injection Moulding & Supply Chain

We support clients throughout production by supplying prototype or manufactured parts during development, keeping progress transparent and collaborative. For UK customers, we offer ongoing production supply. When tooling remains overseas, our streamlined logistics ensure efficient delivery, enabling a smooth bridge between design, tooling and full production.

Why Liondell?

Why Choose Us

Liondell offers a unique combination of family-run service, specialist engineering knowledge and flexible UK and global manufacturing support. With experience across design, tooling and production, we provide precise, responsive and trustworthy solutions for projects of all sizes.

Our Difference

Clients choose Liondell for our commitment to accuracy, reliability and long-term performance. Our hands-on engineering background ensures every recommendation is grounded in real manufacturing realities, not theory. We work closely with start-ups, SMEs and established manufacturers, adapting our support to each project’s scale and complexity. By integrating design, tooling and production considerations from the beginning, we reduce risks, shorten development time and help clients achieve smoother transitions into manufacture. At every stage, we prioritise communication, clarity and practical, results-driven decision-making.

Let’s Build Something Together

Liondell is more than a design and tooling provider — we are partners committed to guiding projects from concept to production. Our experience ensures your ideas progress efficiently, confidently and with the precision required for real-world manufacturing success.