Do you want to develop an injection-moulded plastic product? Not sure where to start? Liondell may be your perfect fit.

In this guide we’ll take you through our process in detail- all the information you need will be included in this post.

ABOUT US

Liondell was established in 2016, run as a family business based in the UK. We are a full service supplier in the Plastics Industry including:

- Consultancy

- Design

- Tool Manufacture

- Injection Moulded Parts

Our aim is to save our clients time and money by providing our experience in:

- Mould Design

- Component Design

- Tool Manufacture

- Injection Moulding

Our team includes four project managers, one of which is stationed in the Far East.

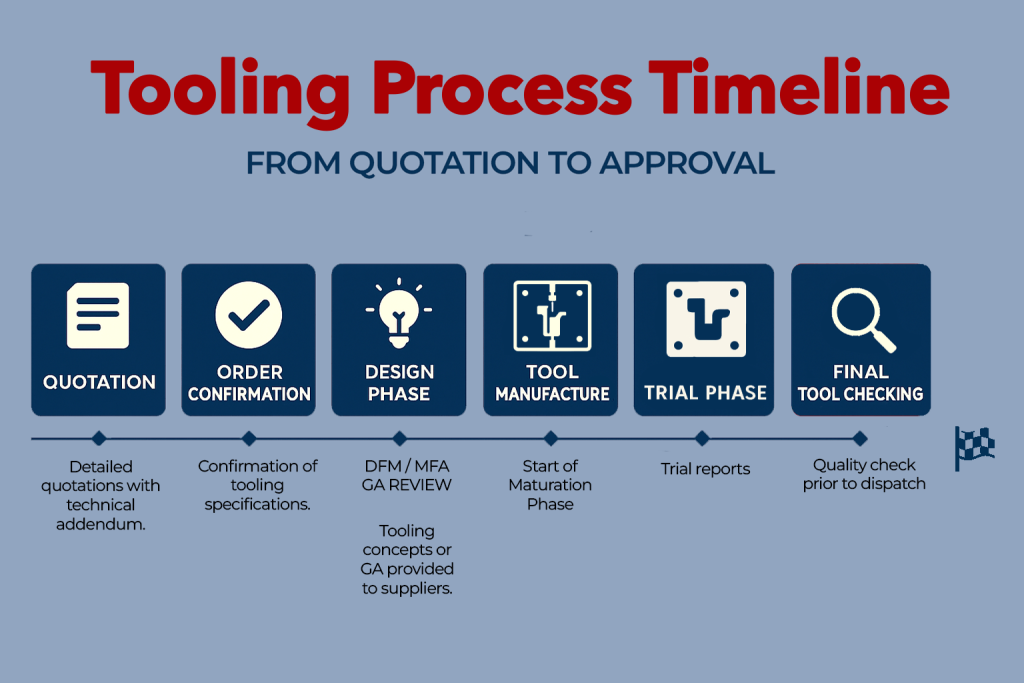

THE PROCESS TIMELINE

OUR PROCESS

DESIGN

We assist in the early design stages which includes assisting with Plastic Part Design, to Design for Manufacture, Flow Analysis and Rapid Prototyping.

- Initial Design Phase

- We meet client’s design briefs for fit, function and aesthetics.

- We use the latest VISI Cad/Flow, Moldex3D and Siemens NX software to ensure that our designs are of the highest quality and are manufacturable.

- Design for Manufacture

This happens when we receive parts to quote. This process ensures that the tooling design is suitable for manufacture.

For mould tooling our attention is focused on the following key features:

- Tool function

- Feed Location

- Part lines

- Wall thickness

- Ejection

For the moulding process our attention is focused on the following key features:

- Tooling dimensions for fit to press/handling considerations

- Feed and material flow – Hot runner or cold feed

- Cooling

- Warp analysis

- Venting

- Ejection of parts – robot or operator handling

- Rapid Prototyping

Rapid prototyping involves quickly creating a physical product/part using various manufacturing techniques, typically 3D printing.

To provide a verified sample prior to tooling, we produce SLA or 3D printed parts for fit and function checking.

In other cases, when part designs are originated by Liondell, we can supply rapid prototypes and or parts from prototype tooling.

Further to our tool design concept, we work with our toolmaking partners on refining a final 3D model for each tool.

Using our comprehensive GA review & checklist process we ensure.

- Compatibility with the client’s press.

- Tool design fit for purpose as dictated by short life warranty.

- Ease of maintenance, change inserts, overmoulding considerations.

We also offer a ‘stand-alone’ tool design service if required.

PRODUCTION

When your part design has been approved and checked, we then use any one of our partners to produce tooling that will make your plastic products.

Our partners who make most of our tools are based in the Far East, we use manufacturers based in that location because:

- Cost and lead times are lower than in the UK and most other global toolmaking centres.

- Established links going back to 2007

- Trusted service and quality

- Responsive to quotation requests

- Dongguan has a tooling-oriented infrastructure that is not found elsewhere. This includes many toolmaking companies, mould base suppliers, ancillary suppliers, and steel and polymers sources to name a few.

MANUFACTURE

We have global toolmaking locations with an approved network of suppliers. The specifications for our toolmaking factories include:

- High quality tooling up to 30 tonnes.

- Certified Steel Grades

- Internation Mould Base Standards & Hot Runner Systems.

Tool Trials

When new tooling is completed, we arrange for tool trials to be conducted in-house or in local trial shops to prove the tooling function and moulding process.

Liondell staff are on-site to assist with the trials to ensure that everything runs smoothly and that the client’s expectations are met.

We give full reports for independent trials, including process parameters so that we can verify and arrange to see a further trial if necessary. If any corrective action is necessary, corrective action (PFU) reports are completed to improve the results at the following trial.

ISIR reports are submitted after every trial. All of our suppliers own or have access to CM Machines and other inspection equipment necessary to produce accurate reports.

Our project manager will attend to ensure the following:

- Material and ancillary inserts are available and used effectively during the trial

- Correct moulding press used

- Cycle time target achieved

- Ejection of parts is feasible

- Parts are untrimmed unless specified

- The quantity of parts produced is correct to order

- Parts are packed and protected adequately for transit

Tool Delivery

With our trusted partners in China and in the UK, we can supply larger batch runs and can put the necessary measures in place to provide just-in-time supply to any global site that clients may request. We have experience in supplying high-volume production products to industries such as Automotive and Aerospace.

We understand quality expectations are high and lead times are strictly adhered to. The tooling we supply is warrantied globally for a set number of cycles (shot-life)

Most clients that we work for are moulders who will make their own arrangements, but occasionally this is not the case.

For manufacturers outside of China, our moulding clients based across mainland UK and Northern Ireland are usually interested in quoting to produce parts locally should a company need a home for their tooling project.

WHY CHOOSE LIONDELL?

Utilising a trusted network of approved suppliers, Liondell provides a first-class service which is managed in a professional and methodical way.

The advantages of choosing Liondell over going direct to an overseas supplier are:

- Ease of communication with our UK clients.

- We assume all project management, saving the client time and money.

- We know the process from start to finish- the client may not have the capabilities to convert designs into reality.

- We provide a tooling warranty with UK support.

- We take the currency risk- giving one firm price.

Read our testimonials to find out more about how our past clients have found working with Liondell

Ready to start your injection-moulding journey with Liondell? Contact us to enquire further