Plastic Product & Part Design

Liondell transforms your product concepts into precise, manufacturable plastic components through expert design, engineering insight and decades of industry experience.

With over fifty years of combined expertise, Liondell delivers plastic part designs that balance innovation with practical manufacturability, ensuring each component performs reliably in production. Our team supports new product creation, enhances existing designs, and converts components to plastic, using a thorough, design-led process that reduces risk, shortens development cycles, and moves your project confidently toward market readiness every time.

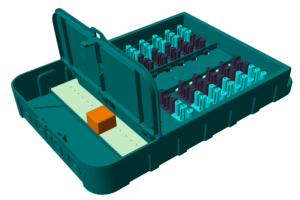

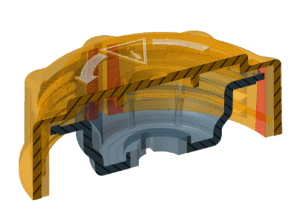

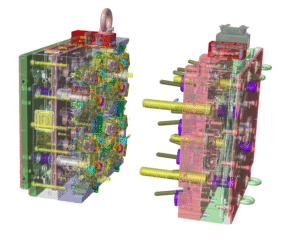

Our end-to-end design capability covers every stage of development, from accurate CAD modelling through to prototype creation and design-for-manufacture validation. We focus on producing detailed, production-ready files that streamline tooling and minimise potential issues later in the process. By combining technical expertise and practical engineering insight, we ensure your component performs reliably in real-world conditions.

Businesses across the UK and Europe choose Liondell for our precision, reliability and long-standing industry experience. As a UK-based, family-run team, we offer a personal, collaborative approach backed by decades of proven results. Clients rely on us for designs that deliver long-term performance, seamless support from initial concept to tooling, and a track record of success across multiple manufacturing sectors.

Our design expertise spans a wide variety of industries, including automotive, medical and healthcare devices, electronics, consumer products and industrial packaging solutions. Each sector brings its own technical considerations, regulatory requirements and performance expectations. We apply sector-specific knowledge to create components that are both practical to produce and engineered for consistent, reliable performance.

Liondell’s design-to-production process follows a structured workflow to maintain accuracy and speed. We begin with a focused consultation to understand your requirements, followed by concept development and CAD modelling. Simulation and validation allow us to identify risks before tooling, while prototype development supports iterative refinement. We conclude with a production-ready design package prepared for seamless handover into manufacture.

If you are ready to take your plastic product from concept to production, Liondell provides the expertise to guide every stage. Our focus on precision, manufacturability and dependable performance ensures your component is built for long-term success. Speak to our design team to discuss your project or begin your next phase of development through a scheduled call or detailed quote request.

How to get started

Next steps

1

Contact

us

Call or send us an email with your project requirements.

2

We Respond

We will acknowledge your inquiry and aim to respond within 24 hours

3

Project Launch

Our goal is to make our clients happy with the whole process and the results within the agreed timeline.

It starts with a 5-minute introduction call